Iron has accompanied humans since the Iron Age, but there is no precedent for using iron as a bioresorbable implant material in tissue repair.

In order to use iron as a bioresorbable implant, it is necessary to solve the problem of slow degradation of iron in alkaline environment of human body and the problem of many solids degradation products of iron in human environment, which is difficult to be cleaned.

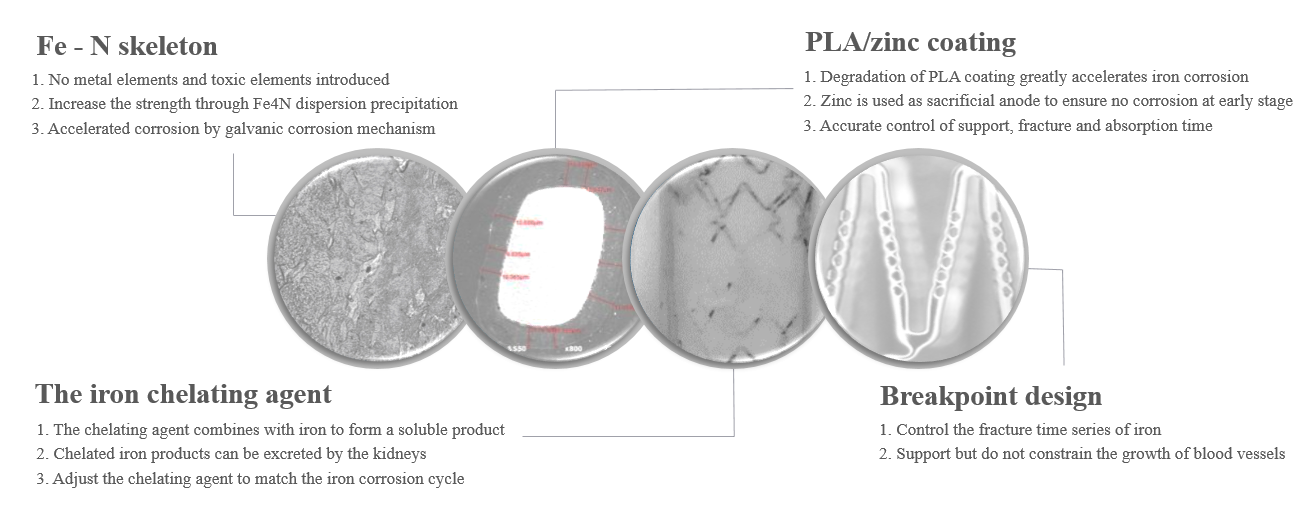

After more than 10 years of research and development, Biotyx Medical (shenzhen) Co., Ltd. has successfully solved these problems, which are summarized in the following four aspects, as shown in the figure above.

1.By introducing 0.05% of nitrogen into the iron, the dispersion precipitation of the second phase Fe4N was formed in the iron through subsequent drawing deformation and heat treatment. On the one hand, through the diffusion strengthening mechanism, the mechanical properties of the material are greatly improved. Therefore, the use level of iron can be highly reduced under the same mechanical properties, For example, our IBS is thinner than the human hair. The reduction of materials can shorten the degradation cycle and reduce the degradation products. At the same time, the degradation of iron materials was accelerated by the galvanic corrosion mechanism between Fe4N and iron. Besides, both Fe and N are very safe elements without other non-degradable metal elements or toxic elements, which ensures the biocompatibility of the material. The reduction of materials also reduces the adverse effect of its magnetic properties on MRI, ensuring that the MR compatibility of iron scaffold is the same as that of other permanent stent.

2.The degradation rate and product morphology of iron in human body were controlled by surface coating. Under acid condition, iron can quickly degrade into soluble iron ions. Therefore, we apply polylactic acid coating on the surface of iron substrate. During the degradation process, these coatings release hydrogen ions to reduce the local pH value, so that iron can be dissolved into soluble iron ions very quickly. These iron ions can be combined by blood cells and introduced to the normal iron circulation of human body. The iron ions entering the tissue will be precipitated into the dispersive iron degradation products because of the increase of pH value in the tissue, but these dispersive products are easily swallowed by macrophages, and they will be transformed into hemosiderin through the strong acid environment in macrophages and introduced to the normal iron cycle of human body. The integrity of the implant must be maintained for a certain period in the early stage, so we coated a nano-thick pure zinc layer between polylactic acid and iron substrate. Zinc layer acts as the sacrificial anode to ensure that the iron substrate does not degrade until zinc fully degraded. An ideal degradation curve can be obtained by the regulation of weight and molecular weight of PLA and zinc. That is, iron does not degrade in a certain period in the early stage and degrades rapidly after the vascular remodeling is completed

3.The iron chelating agent can combine with the iron in the human body to form iron chelation. This iron chelation does not precipitate as iron particles in the human body, but is excreted through the kidneys. This is a conventional treatment for iron overload in patients with repeated blood transfusions. The introduction of an appropriate iron chelating agent in iron implants can significantly reduce the deposition of iron particles and greatly reduce the time it takes for iron implants to be locally absorbed.

4.Breakpoint or cross-section variable cross-section design can establish the fracture time series of iron implants. Small sections are set where the fracture is needed in advance, especially like a child stent, where the external support is needed before the vascular shaping is completed, and there is no resistance to the growth of blood vessels during the process of vascular growth. Appropriate fracture time series can guarantee this unidirectional force. Although the breakpoint has been broken, it can still bear the pressure of internal contraction of blood vessel under the tissue constraint. However, if the blood vessel grows outward, the existence of the breakpoint will not impede the growth of blood vessel at all.

The combination of the above four points in different products can solve the problems of iron as an absorbable implant. Therefore, compared with other bioabsorbable materials, the advantages of iron in mechanical properties and molding ability can be fully exerted.